Acrylic Brushed Paint OEM Elastomeric Wall Coating Elastic Coating Pure Art Elastomeric Wall Coating

Application Method

Brush

Feature

Eco-friendly low cost easy to operate

Usage

Appliance Paint, Building Coating, old house roofs, bridges, tunnels, grounds, basements, balconies

Application scope

old house roofs, bridges, tunnels, grounds, basements, balconies, etc.

Brushing Area:1 kilograms 8 square meters

| Name |

Elastic Coating Exterior Latex Wall Paint |

| Main Raw Material |

Acrylic |

| Usage |

Building Coating, Exterior Wall Paint |

| MF |

C3H4O2 |

| Application Method |

Roller, Brush, Spraying |

| State |

Liquid Coating |

| Color |

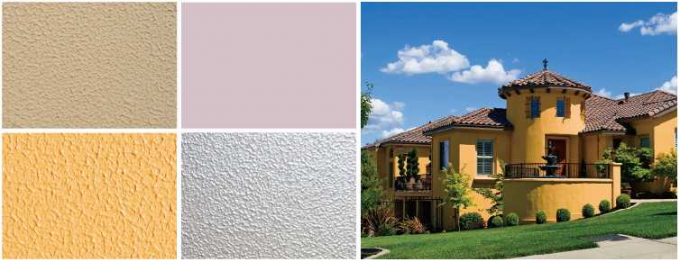

Customize |

| Touch Dry |

30 Min |

| Package Type |

Iron Can In Paper Carton. |

Introduction:

Elastic coating is a kind of high solid and high elastic composition coating made of advanced elastic

emulsion and high quality inorganic raw materials. It can effectively cover the fine cracks in the wall

and is also the best choice for repainting the old wall.

Features:

• Prevention: It can prevent water and carbon dioxide from penetrating into the wall, keep the

alkalinity of concrete forever, and solve the problem of steel rusting.

• Waterproof, anti-freezing and temperature-resistant function: can prevent water infiltration into the

wall, avoid cold and freeze to produce qualitative change, excellent initial water resistance.

• Dirt resistance: The application of core-shell technology, soft core interconnecting, hard core

outside. The soft core ensures the elasticity of the film, and the hard core reduces the adhesion of the

film and improves the resistance to contamination.

• High weather resistance: resin coating made by three-dimensional cross-linking reaction is highly

weather-resistant and can protect the appearance of buildings for a long time.

• Other advantages: Strong adhesion, elegant luster, long-term high elasticity, and solve pinhole

problems.

Application:

Building interior wall, exterior wall, line board, decorative modeling, special modeling, etc.

Applicable base surface:

Cement mortar surface, concrete surface, plasterboard, wood board, all kinds of fiberboard, metal

plate, etc.

Surface requirements:

Cement base: use cement slurry or special putty to smooth plastering surface defects or hollows.

Wood base: clean up, then spray oil seal primer.

Metal base: grind the base with 360# sandpaper, clean it with appropriate chemical solvent, and then

coat with special primer.